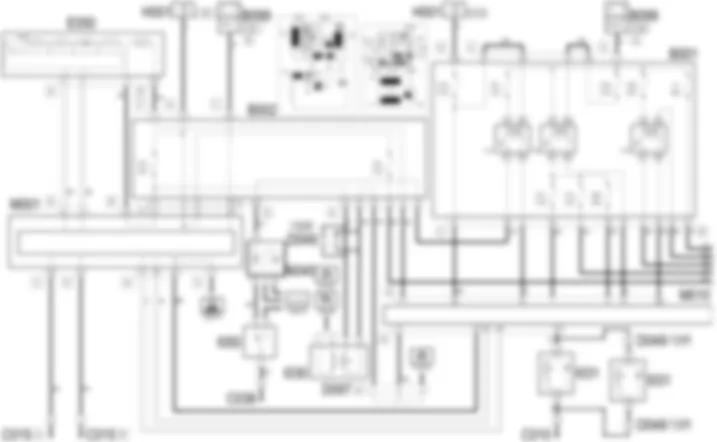

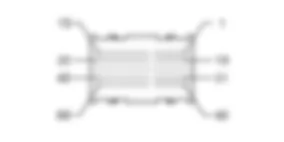

Wiring diagram - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

Components - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

| Component code | Name | Assembly reference |

| A40 | HEATER PLUGS (CYL. 1) | |

| B1 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| C1 | BATTERY EARTH | - |

| D4 | FRONT/ENGINE CONNECTION ( CONNECTORS ) | - |

| I31 | CLUTCH PEDAL SWITCH ( FRONT ) | 1056B |

| I31 | CLUTCH PEDAL SWITCH ( FRONT ) | |

| K100 | TEMPERATURE SENSOR AND CO HEATING RESISTANCE | - |

| K30 | ENGINE OIL PRESSURE SENSOR SWITCH ( CONNECTORS ) | |

| K31 | WATER IN DIESEL FILTER SENSOR | |

| K36 | ENGINE TEMPERATURE SENDER UNIT ( CONNECTORS ) | |

| K41 | AIR FLOW METER ( FRONT ) | |

| K46 | RPM SENSOR ( CONNECTORS ) | |

| K47 | TIMING SENSOR. ( CONNECTORS ) | |

| K55 | ACCELERATOR PEDAL POTENTIOMETER ( FRONT ) | |

| K82 | TURBOCHARGING SENSOR | |

| K83 | FUEL PRESSURE SENSOR | |

| L30 | EGR SOLENOID | |

| L36 | VARIABLE GEOMETRY TURBINE SOLENOID VALVE ( CONNECTORS ) | |

| L62 | BUTTERFLY CASING SOLENOID VALVE | - |

| M1 | BODY COMPUTER | |

| M10 | ENGINE MANAGEMENT ECU | |

| M15 | PLUG PREHEATING CONTROL UNIT | - |

| N70 | INJECTOR | |

| N77 | FUEL PRESSURE REGULATOR ( CONNECTORS ) | - |

Location of components - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

Components - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

| Component code | Name | Assembly reference |

| A40 | HEATER PLUGS (CYL. 1) | |

| B1 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| C1 | BATTERY EARTH | - |

| D4 | FRONT/ENGINE CONNECTION ( CONNECTORS ) | - |

| I31 | CLUTCH PEDAL SWITCH ( FRONT ) | 1056B |

| I31 | CLUTCH PEDAL SWITCH ( FRONT ) | |

| K100 | TEMPERATURE SENSOR AND CO HEATING RESISTANCE | - |

| K30 | ENGINE OIL PRESSURE SENSOR SWITCH ( CONNECTORS ) | |

| K31 | WATER IN DIESEL FILTER SENSOR | |

| K36 | ENGINE TEMPERATURE SENDER UNIT ( CONNECTORS ) | |

| K41 | AIR FLOW METER ( FRONT ) | |

| K46 | RPM SENSOR ( CONNECTORS ) | |

| K47 | TIMING SENSOR. ( CONNECTORS ) | |

| K55 | ACCELERATOR PEDAL POTENTIOMETER ( FRONT ) | |

| K82 | TURBOCHARGING SENSOR | |

| K83 | FUEL PRESSURE SENSOR | |

| L30 | EGR SOLENOID | |

| L36 | VARIABLE GEOMETRY TURBINE SOLENOID VALVE ( CONNECTORS ) | |

| L62 | BUTTERFLY CASING SOLENOID VALVE | - |

| M1 | BODY COMPUTER | |

| M10 | ENGINE MANAGEMENT ECU | |

| M15 | PLUG PREHEATING CONTROL UNIT | - |

| N70 | INJECTOR | |

| N77 | FUEL PRESSURE REGULATOR ( CONNECTORS ) | - |

Description - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

An electronic management system supervises and governs all engine parameters. It optimises performance and fuel consumption by responding in real time to different service conditions.The common rail injection system on this version with 4 valves per cylinder uses Multijet technology: i.e. it carries out more than the usual two injections during each engine cycle: it carries out two pre-injections (before the piston is at TDC), one main injection and two post-injections.This solution improves consumption, emissions, quietness and performance because it allows better control of the temperature in the combustion chamber, lowering the maximum value and extending the optimum combustion zone.The system uses signals received from numerous sensors to control actuators. It is connected to the following systems:fuel supply;air supply system;heater plugs;accelerator pedal;engine cooling;fuel preheating.

For greater detail, see.Thanks to the electronic management described above, this engine conforms to the latest anti-pollution and continuous control regulations in accordance with the EOBD system (European On Board Diagnosis);The EOBD (European On Board Diagnosis) system carries out continuous diagnosis of the car''s petrol fuel system components relating to emissions and indicates any deterioration of these components by the warning light in the instrument panel coming on.The aim of the system is:keeping the efficiency of the system under control;signalling an increase in emissions due to a vehicle malfunction;signalling the need to replace components which have deteriorated.

The system is also controlled by means of special relays located in the engine compartment unit; the supply lines to the control unit and the various system components (sensors and actuators) are protected by special fuses, also located in the engine compartment.

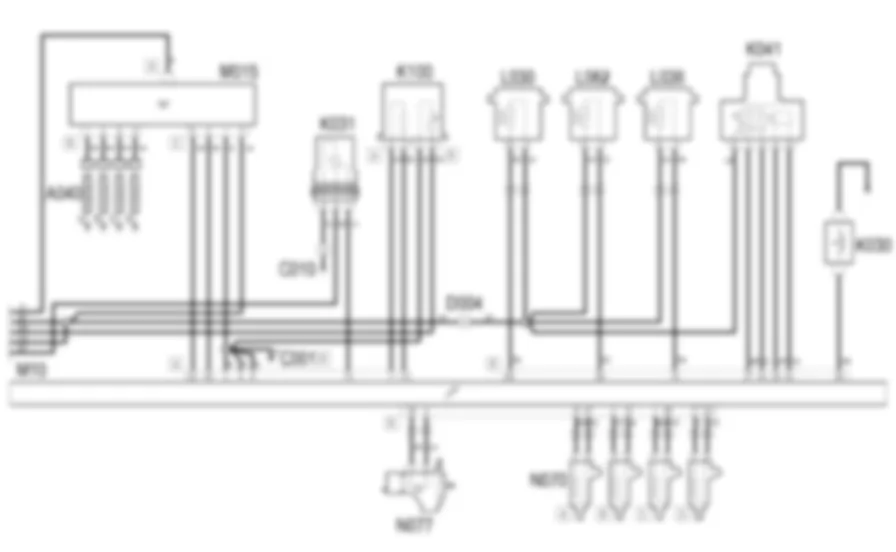

Functional description - DIESEL ENGINES ELECTRONIC MANAGEMENT - Alfa Romeo GT 1.9 JTD 16V

The engine control unitM10monitors and controls the entire electronic injection system.The system is supplied directly by the battery via a line protected by the maxifuse CVM located on the battery, connectorB99.The supply controlled by the ignition (15/54) reaches pin 28 of connector A ofM10 from the line protected by fuse F16 of the engine compartment unit B1.The fuel pump relay T10 ofB1is supplied from the line of fuse F21 ofB1The main injection relay T9 of B1 controls the entire system; the supply line is protected by fuse F18 of B1; it is energized by a control signal (earth) coming from pin 72 of the control unit M10, and thus sends a supply:to pin 1 of connector A of the actual control unit, via the line from fuse F17 of B1;to pin 5 of connector A of the actual control unit, via the line from fuse F22 of B1;to the air flow meter K41, to the solenoid valves L30, L36; L62 , to the control unit M15 , via the line from fuse F11 of B1

.It is energized by a control signal (earth) from pin 91 of connector A of control unitM10 and supplies power to fuel pump N40, which is earthed through the inertia switch I50, which cuts off the circuit in the case of a crash and so prevents the dangerous spilling of fuel.Pins 2, 4 and 6 of connector A ofM10 are earthed.The diesel pre-heating relay T19 ofB1is supplied by the line for fuse F20 ofB1.It is energized by a control signal (earth) coming from pin 68 of connector A of the control unitM10 and supplies power to the diesel heating resistance located in K100, connector B.Control unitM15, responsible for controlling preheating of heater plugsA40, is supplied directly by the battery via a line protected by fuse F1 ofB1. It is supplied, connector C, by the line for fuse F11 ofB1and exchanges command and control signals with pins 52 and 93 of connector A ofM10which controls the timing. Connector B is connected to the heater plugsA40.The engine control unitM10receives signals from the various sensors in order to monitor all engine service conditions.Rpm sensorK46 supplies information on engine speed via a frequency signal sent to pins 12 and 27 of connector B of control unit M10.Timing sensorK47 is supplied from pin 11 of connector B of control unit M10.It receives a reference earth from pin 20 of connector B of control unitM10 and sends it a signal of frequency corresponding to the timing of pin 50 of the same connector.The engine temperature sensorK36, receives a reference earth from pin 41 of the control unitM10and supplies a signal proportional to the temperature of the engine coolant to pin 58 of connector B.The air flow meterK41 receives a general supply from the line for fuse F11 of B1 and a reference earth from pin 44 of connector B of M10.It is supplied by the control unit from pin 29 of connector B ofM10, and sends pin 42 of connector B a signal proportional to the air flow.There is also an air temperature sensor insideK41 which sends an air temperature signal to pin 37 of connector B of M10.Accelerator pedalK55 is fitted with two built-in potentiometers (a main one and a safety back-up).The former receives power and earth from pins 30 and 45, respectively of connector A ofM10 and sends a corresponding signal to pin 9.The latter receives power and earth from pins 46 and 8, respectively of connector A ofM10 and sends a signal to pin 31.The fuel temperature sensor, located inK100, connector A, measures the temperature of the diesel entering.It receives a reference earth from pin 10 of connector A ofM10 and sends the fuel temperature signal to pin 11.The supercharging sensorK82 measures the pressure and temperature in the intake chamber, downstream of the turbocharger.It is supplied from pin 13 of connector B ofM10 and receives a reference earth from pin 23 of connector B.The signal corresponding to the pressure value is sent to pin 40 of connector B of the control unit. There is also an air temperature sensor insideK82 which sends a signal to pin 53 of connector B of M10.The fuel pressure sensorK83is responsible for providing the injection control unit with a feedback signal for governing pressure and injection duration. It receives power and a reference earth from pins 28 and 8 respectively of connector B ofM10;it then sends the pressure signal to pin 43.The fuel pressure regulatorN77has the task of keeping the value of the fuel pressure in the accumulator constant. The two control signals come from pins 4 and 34 of connector B of the control unitM10.The EGR solenoidL30controls exhaust gas recirculation. it is supplied by the line for fuse F11 ofB1 and is controlled by a signal for pin 60 of connector B of M10.The variable geometry solenoid valveL36 regulates the operation of the turbine according to the engine load: it is supplied by the line for fuse F11 of B1 and is controlled by a signal for pin 15 of connector B of M10.The solenoid valve on the throttle casingL62 shutters and closes the throttle, for example when the engine is switched off;it is supplied by the line for fuse F11 ofB1and is controlled by a signal for pin 59 of connector B ofM10.Pin 17 of connector A ofM10 receives the signal coming from the brake lights switch I30, with the supply controlled by the ignition (INT) from fuse F37 of the junction unit B2.Pin 79 of connector A ofM10 receives the signal coming from the clutch switch I31.The injectorsN70receive the opening go ahead supply from pins 117 (cylinders 1 and 2) and 118 (cylinders 3 and 4) ofM10.The engine management control unit sends the command to the injectorsN70 from pins 16-47, 2-31, 1-46, 17-33 of connector B of M10 for cylinders 1, 2, 3 and 4, respectively.The control unitM10 receives the signal for the minimum engine oil pressure sensor K30 at pin 35 of connector B.The water in diesel filter sensorK31; is supplied by the line controlled by the ignition (INT) for fuse F51 ofB2 and sends the corresponding signal to pin 74 of connector A of M10.The self-test data can be read by connecting to connector G of the Body ComputerM1 - pin 7: it receives the signals from pin 25 of connector A from the control unit M10 via the specific tester line.The control unit M10 is connected via the CAN network to the Body Computer M1 and the other nodes on the network: through this connection, it sends information concerning:the system self-diagnosis, which can be used by connecting to connector G of M1 engine coolant temperature which is sent to the instrument panel E50 which manages the indicator and warning light;rpm, which is sent to the rev counter of the instrument panel E50 ;engine oil minimum pressure, which is sent to instrument panel E50 which manages the relevant warning light;heater plugs pre-heating, which is sent to the instrument panel E50 which manages the appropriate warning light;water in diesel filter, which is sent to the instrument panel E50 which manages the display.It receives, via CAN, the speedometer signal generated by the ABS control unit M50The self-test system of the control unit M10 also generates a signal - which comes from pin 71 of connector A - which is connected directly to the ''EOBD'' warning light located in the instrument panel E50.

Heater plug

A40A

A40B

A40C

A40D

Engine compartment junction unit

B1A

B1A

B1A

B1B

B1B

B1B

B1C

B1C

B1C

B1D

B1E

B1E

B1X

B1X

Junction unit under dashboard

B2A

B2A

B2A

B2A

B2A

B2A

B2B

B2B

B2C

B2C

B2D

B2E

B2F

B2G

B2H

Battery earth

C1A

C1A

C1A

C1B

C1C

Front/engine connection

D4

D4A

D4A

D4A

D4B

D4B

D4

D4

D4

Clutch pedal switch

I31

I31

I31

Fuel heating resistance and temperature sensor

K100A

K100B

Engine oil pressure sensor switch

K30

K30

K30

Water in diesel filter sensor

K31

Engine temperature sender unit

K36

K36

K36

Air flow meter

K41

K41

K41

Rpm sensor

K46

K46

K46

Timing sensor.

K47

K47

K47

Accelerator pedal potentiometer

K55

K55

K55

Turbocharging sensor

K82

Fuel pressure sensor

K83

K83

EGR solenoid

L30

Variable geometry turbine solenoid valve

L36

Butterfly casing solenoid valve

L62

Body computer

M1A

M1A

M1A

M1A

M1A

M1A

M1B

M1C

M1D

M1E

M1F

M1G

Engine management control unit

M10A

M10A

M10A

M10B

M10B

M10B

Plug preheating control unit

M15A

M15B

M15C

Injector

N70A

N70A

N70A

N70B

N70B

N70B

N70C

N70C

N70C

N70D

N70D

N70D

N70E

N70F

Fuel pressure regulator

N77

N77