Components - METHANE ENGINE ELECTRONIC MANAGEMENT - Fiat DOBLO 1.6 16v Da 10/2000

| Component code | Description | Reference to the assembly |

| A030 | IGNITION COIL | |

| B001 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| B40 | FUEL INJECTION SERVICES SUPPLY FUSE | |

| C011 | RIGHT FRONT EARTH | |

| C15 | DASHBOARD EARTH, DRIVER''S SIDE | |

| C030 | LEFT REAR EARTH | |

| C60 | INJECTION ECU EARTH | |

| C62 | METHANE INJECTION CONTROL UNIT EARTH | |

| D004 | FRONT/ENGINE COUPLING | |

| D006 | FRONT/REAR COUPLING | |

| D81 | INJECTOR COUPLING | |

| E50 | INSTRUMENT PANEL | |

| H001 | IGNITION SWITCH | |

| H95 | PETROL/METHANE SWITCH | |

| I050 | INERTIA SWITCH | |

| J25 | METHANE SOLENOID RELAY | |

| J26 | METHANE/LPG RELAY FEED | |

| K15 | LAMBDA SENSOR ON PRE-CATALYZER | |

| K17 | LAMBDA SENSOR ON CATALYZER | |

| K30 | ENGINE OIL PRESSURE SENSOR (SWITCH) | |

| K36 | ENGINE COOLANT TEMPERATURE SENSOR/SENDER UNIT | |

| K43 | INTEGRATED AIR TEMPERATURE SENSOR | |

| K46 | RPM SENSOR | |

| K47 | TIMING SENSOR. | |

| K50 | DETONATION SENSOR - 1 | |

| K54 | METHANE PRESSURE SENSOR | |

| K56 | THROTTLE POSITION SENSOR | |

| K57 | METHANE PRESSURE AND TEMPERATURE SENSOR ON MANIFOLD ( ENGINE ) | |

| K84 | SPEEDOMETER SENSOR | |

| L10 | FUEL VAPOUR RECOVERY SOLENOID | |

| L60 | METHANE SUPPLY SOLENOID | |

| L061 | METHANE REGULATION SOLENOID | |

| M001 | BODY COMPUTER | |

| M010 | ENGINE MANAGEMENT ECU | |

| M19 | METHANE INJECTION CONTROL UNIT | |

| N040 | FUEL PUMP AND LEVEL GAUGE | |

| N70 | INJECTOR | |

| N72 | METHANE INJECTOR | |

| N74 | IDLE ACTUATOR |

| Component code | Description | Reference to the assembly |

| A030 | IGNITION COIL | |

| B001 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| B40 | FUEL INJECTION SERVICES SUPPLY FUSE | |

| C011 | RIGHT FRONT EARTH | |

| C15 | DASHBOARD EARTH, DRIVER''S SIDE | |

| C030 | LEFT REAR EARTH | |

| C60 | INJECTION ECU EARTH | |

| C62 | METHANE INJECTION CONTROL UNIT EARTH | |

| D004 | FRONT/ENGINE COUPLING | |

| D006 | FRONT/REAR COUPLING | |

| D81 | INJECTOR COUPLING | |

| E50 | INSTRUMENT PANEL | |

| H001 | IGNITION SWITCH | |

| H95 | PETROL/METHANE SWITCH | |

| I050 | INERTIA SWITCH | |

| J25 | METHANE SOLENOID RELAY | |

| J26 | METHANE/LPG RELAY FEED | |

| K15 | LAMBDA SENSOR ON PRE-CATALYZER | |

| K17 | LAMBDA SENSOR ON CATALYZER | |

| K30 | ENGINE OIL PRESSURE SENSOR (SWITCH) | |

| K36 | ENGINE COOLANT TEMPERATURE SENSOR/SENDER UNIT | |

| K43 | INTEGRATED AIR TEMPERATURE SENSOR | |

| K46 | RPM SENSOR | |

| K47 | TIMING SENSOR. | |

| K50 | DETONATION SENSOR - 1 | |

| K54 | METHANE PRESSURE SENSOR | |

| K56 | THROTTLE POSITION SENSOR | |

| K57 | METHANE PRESSURE AND TEMPERATURE SENSOR ON MANIFOLD ( ENGINE ) | |

| K84 | SPEEDOMETER SENSOR | |

| L10 | FUEL VAPOUR RECOVERY SOLENOID | |

| L60 | METHANE SUPPLY SOLENOID | |

| L061 | METHANE REGULATION SOLENOID | |

| M001 | BODY COMPUTER | |

| M010 | ENGINE MANAGEMENT ECU | |

| M19 | METHANE INJECTION CONTROL UNIT | |

| N040 | FUEL PUMP AND LEVEL GAUGE | |

| N70 | INJECTOR | |

| N72 | METHANE INJECTOR | |

| N74 | IDLE ACTUATOR |

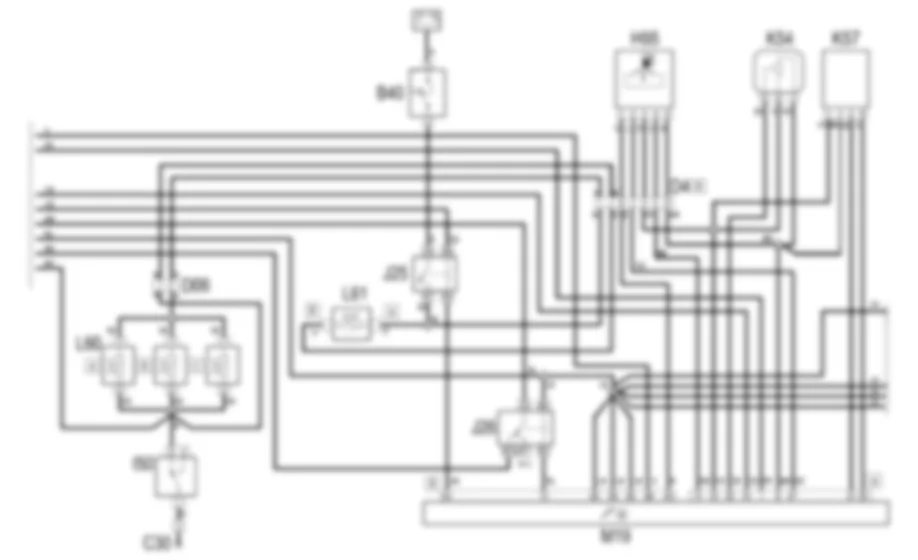

The petrol supply system is managed by a control unit that also controls both ignition and injection.The methane supply system is managed by another control unit that controls methane injection and the switching logic for the methane/petrol fuel system which takes place automatically or manually, using the special switching button in the dashboard.Both control units are inter-connected by a CAN network.The engine management can be optimised under all operating conditions and with any type of fuel system due to the continuous communication between them.Depending on the signals received from the numerous sensors, the two control units, which share some signals from certain sensors, operate the respective actuators that are connected, managing the following systems:- petrol supply;- methane supply;- air supply;- engine cooling;- fuel vapour recirculation;- control of combustion - Lambda sensors;- control of exhaust with catalytic silencer.The current version of the system also includes the EOBD function (European On Board Diagnosis) - that allows the continuous fault diagnosis of the components for petrol operation correlated with emissions and signals the deterioration of any of these components by switching on the injection/EOBD system warning light (amber).The diagnostic system includes:- the catalytic silencer which, in the case of a malfunction, does not convert the pollutants produced by the engine;- the Lambda sensors (oxygen sensors);- misfire, where the unburnt fuel reaches the catalyzer where the thermal conversion reactions produce a sudden increase in temperature damaging the actual catalyzer.The methane system complements the basic system and the operation of the basic system is not affected in all operating conditions.The specific control unit manages the phased, sequential methane injection and the activation of the (methane) gas cut out solenoid valves in addition to the deactivation of the petrol pump.Injection takes place directly through the operation of the specific methane system injectors.The ignition advance is achieved by sending the basic electronic unit the advance variation to be added to the one for petrol operation.This communication takes place through the CAN network.The methane electronic unit uses the signal from the methane perssure and temperature sensor on the manifold to correct the injection times, thereby controlling the exhaust emissions which are within the current regulations - EOBD -.If the control unit identifies a serious fault (e.g. in the methane injectors) switching to petrol operation is automatic and, at the same time, this is signalled via the instrument panel.If the unit identifies a less serious fault, this is signalled but methane operation continues.All the other engine management functions, including the ignition advance, are left to the basic engine management control unit.768 767 768

Engine management control unit M10 controls and governs the entire electronic ignition and injection system.The control unit M10 receives a direct supply from the battery at pin 29 of connector A via the line protected by fuse F18 of engine compartment unit B1.The ignition-operated power supply (15/54) arrives via a line protected by fuse F16 of the engine compartment junction unit B01 at pin 47 of connector A of M10 .The main injection relay F9 of B01 controls the entire system: it is energized by an earth signal from pin 15 of connector A of engine control unit M10 and then forwards a power supply:- to coils A30 and injectors N70 via a line protected by fuse F22 of B01.- to fuel pump N40 via petrol supply relay J26 controlled by pin 74 of methane injection control unit M19 that deactivates pump N40 during methane engine operation via a line protected by fuse F22 of B01.- to the fuel vapour recovery solenoid, to lambda sensors K15 and K17 and to speedometer generator K84 via a line protected by fuse F11 of B01.Pump N40 is connected to earth via inertia switch I50 that cut off the circuit in the event of impact to stop the dangerous outflow of fuel.Pins 27 and 28 of connector A of M10 are earthed.The engine management control unit M10 receives signals from the various sensors thereby keeping all the engine operating parameters under control.The rpm sensor K46 provides information, via a frequency signal sent to pins 53 (positive) and 67 (negative) of connector B of the control unit M10, about the engine speed. hese two signals are very low intensity and are thus appropriately shielded (pin 77 connector B).Timing sensor K47 is supplied from pin 68 of connector B of M10 . It receives a reference earth from pin 54 of connector B and sends a signal with frequency corresponding to the fuel pressure to pin 69 of control unit connector B of M10.Integrated air temperature sensor K43 receives a reference earth from pin 54 of connector B; it sends a signal corresponding to intake air temperature to pin 55 connector B of the control unit.Pin 68 of connector B of M10 sends a reference power supply to sensor K43 , which returns a signal proportional to intake air pressure to pin 75 connector B.Throttle position sensor K56 receives a 5V supply from pin 60 connector B and receives a reference earth form pin 54 connector B. It sends a signal proportional to the throttle opening level via a potentiometer to pin 76 connector B of M10.The engine temperature sender unit K36 receives a reference earth from pin 54 of connector B of the control unit M10 and provides a signal proportional to the temperature of the engine coolant at pin 62 of connector B of the control unit.The detonation sensor K50 provides information, by means of frequency signals, concerning the onset of detonation in the combustion chamber: it sends two signals to pins 56 (positive) and 70 (negative) of connector B of M10 ; these signals are also appropriately shielded (pin 63 connector B).The Lambda sensor on the pre-catalyzer K15 and the one on the catalyzer K17 provide the control unit M10 with information concerning the correct composition of the air-fuel mixture.The sensor K15 sends a signal to pin 20 of connector A of the control unit, while pin 9 connector A provides a reference earth: hese two signals are very low intensity and are thus appropriately shielded (pin 44 connector A of engine control unit M10).Sensor K15 is heated by a resistance to ensure correct operation even when cold; the resistance is supplied by relay R9 of B01; pin 1 of connector B of M10 provides the reference earth.The sensor K17 sends a signal to pin 24 of connector A of the control unit, while pin 12 connector A provides a reference earth: hese two signals are very low intensity and are thus appropriately shielded (pin 44 connector A of engine control unit M10).Sensor K17 is heated by a resistance to ensure correct operation even when cold; the resistance is supplied by relay R9 of B01; pin 2 of connector A of M10 provides the reference earth.The control unit M10 receives - at pin 8 of connector A - a signal from the minimum engine oil pressure sensor K30Control unit M10 also controls A30 via control signals for the primary winding of the coil, while the secondary sends a pulse to the spark plugs: from pin 59 connector B for the cylinder pair 1-4 and from pin 66 connector B for cylinders 2-3.The primary windings of coils A30 receive a power supply to enable opening of relay R9 of B01.Idle actuator N74 regulates the throttle by-pass line. This is controlled by control unit M10 via signals from pins 57, 58, 64 and 65 of connector B.The fuel vapour recovery solenoid valve L10 allows the flow of fuel vapours to the engine intake where they are added to the mixture entering the combustion chamber.Valve L10 is supplied from relay R9 of B01; it is opened by the control unit when the engine is loaded via a signal from pin 52 of connector A of engine control unit M10 .The control unit M10 is connected via the C-CAN - pins 6, 32 of connector A - to the Body Computer M01 and to the other network nodes; it sends information concerning the following via this connection:- system self-diagnosis, that can be used by connecting to connector B of M01:- a fault in the injection system and/or indication of incorect exhaust gas emissions - EOBD (fault displayed by an amber warning light on the control panel E50).- engine coolant temperature, which is sent to the instrument panel E50 which manages the gauge and the warning light;- engine rpm, which is sent to the instrument panel E50 rev counter;- minimum engine oil pressure, which is sent to the instrument panel E50 which manages the warning light.Recives a speedometer signal generated by sensor K84 via the CAN network.The self-diagnostic data may be read by connecting connector C of Body Computer M1 to pin 7, which receives signals from pin 25 of connector A of control unit M10 via the appropriate diagnostic line.The methane injection control unit M19 processes the information coming from the basic system sensors, that coming via the CAN line from control unit M10 (coolant temperature, air temperature) and the information coming from the additional sensors for methane operation in order to recognize the system operating conditions and produce suitable commands for the methane injectors.The control unit M19 receives a direct supply from the battery at pin 1 of connector A - via the line protected by fuse F18 of engine compartment unit B01.An ignition-operated power supply (INT) reaches pin 34 of connector A of methane injection control unit M19 from a line protected by fuse F35 of dashboard control unit B02.Pins 27, 28 of connector A and 55, 61, 62 and 76 connector B of control unit M19 are earthed.A CAN line leads from pins 23 and 38 of M19 toward control unit M10, Body Computer M01 and the other network nodes.The main methane supply relay R10 of engine compartment control unit B01 is supplied directly form the battery by a line from fuse 21 of B01 while the coil is supplied by an ignition-operated supply (15/54) from a line protected by fuse F16; this is excited by a control signal (earth) from pin 68 connector B of control unit M19 and then sends a power supply:- to control unit M19, pins 59, 66 and 80 of connector B;- to the coil of fuel supply relay J26;- to methane injectors N72.Switching device H95 (that includes a methane level and operating mode display function in addition to the selector function) receives a power supply and reference earth from methane control unit M19 - pins 16 and 6 of connector A. If the system is switched manually to petrol, it sends a signal to pin 47 of connector A of control unit M19. A methane operation signal leaves pin 10 of connector A of M19.Methane pressure sensor K54 located on the regulation solenoid receives a power supply and reference earth from metane control unit M19 - pins 16 and 6 of connector A = and sends a signal proportional to the methane pressure to control unit M19 - pin 30 of connector A. The connector sends a signal proportional to methane level - from pin 60 connector B - to switching device H95.The methane pressure and temperature sensor K57 is made up of a dual sensor, one resistive (temperature) and the other capacitative (pressure).This is located in the central part of the manifold where the methane injectors are located. It receives a power supply and reference earth from methane control unit M19 - pins 16 and 6 of connector A - and sends a signal proportional to methane pressure in the manifold and a signal relating to methane temperature respectively to pins 31 and 29 connector A of control unit M19.Pins 54 and 74 of connector B of control unit M19 enables the fuel supply type (petrol or methane, mutuallly exclusive) according to the control strategy.Pin 74 disables the petrol operation: it sends an earth signal to the coil of petrol supply relay J26: this is supplied via relay R9 of B01 via a line protected by fuse F22 of B01, while the coil is supplied by relay R10 of B01. When relay J26 is excited, it cuts off the supply to fuel pump N40.Pin 54 enables the methane operation - it sends an earth signal that excites methane operation relay J25: this is supplied by a line protected by special fuse B40 while the coil is ignition-operated (INT) by a line protected by fuse F35 of under-dashboard control unit B02. Once excited, this sends power to methane regulation solenoid L61 and the three solenoids of methane cylinders L60 (A-B-C) located on the methane cylinders (on the Doblo version, there are two cylinder solenoids, A and B).Solenoids L60 and L61 are all connected to earth via inertia switch I50 that cut off the circuit in the event of impact to stop the dangerous outflow of fuel.Control unti M19 receives some signals from the petrol system sensors.The rpm sensor K46 provides information, via a frequency signal sent to pins 51 (positive) and 52 (negative) of connector A of the control unit M19, about the engine speed. these two signals are very low intensity and are thus appropriately shielded.Timing sensor K47 is supplied by pin 68 connector B of M10 and sends a frequency signal corresponding to the phase to pin 12 connector A of M19; a reference earth is sent to pin 11 connector A of M19: these two signals are very low intensity and are thus appropriately shielded.A reference signal is sent from pin 68 connector B of M10 to sensor K43 that returns a signal proportional to intake air pressure to pin 44 connector A of M19. a reference earth is sent to pin 33 connector A of M19: these two signals are very low intensity and are thus appropriately shielded.Throttle position sensor K56 is supplied at 5V from pin 60 connector B of M10. It sends a signal proportional to the level of throttle opening via the potentiometer to pin 43 connector A of M19. A reference earth is sent to pin 32 connector A of M19: these two signals are very low intensity and are thus appropriately shielded.The sensor K15 sends a signal to pin 46 of connector A of control unit M19, while pin 35 connector A receives a reference earth: these two signals are very low intensity and are thus appropriately shielded.Control unit M10 controls - only in the event of petrol operation - the opening of injectors N70 through special signals sent from pins 71, 79, 78 and 72 connector B. Injectors N70 receive a signal to enable opening from relay R9 of B01.Control unti M19 controls - in the event of methane operation only - the opening of injectors N72 through special signals sent from pins 64, 57, 63 and 56 connector B of M19.Methane control unit M19 exchanges information on correct system operation with body computer M01 and othe other network nodes via the CAN line, respectively from pins 23 and 38 connector A to pins 37 and 36 of connector C of the body computer.The self-diagnostic data may be read by connecting connector B of Body Computer M01 (pin 7), which receives signals from pin 3 of connector A of control unit M19 via the appropriate diagnostic line.Control unit M10 is connected to the air conditioning system via pins 21, 35, 41 and 48 connector A.This allows engine idle speed to be adjusted to the increased load whenever the compressor is activated, or deactivated in the event of high speed or high engine load.The control unit also controls the engine cooling system: pins 14 and 40 connector A control activation of the relevant fan.