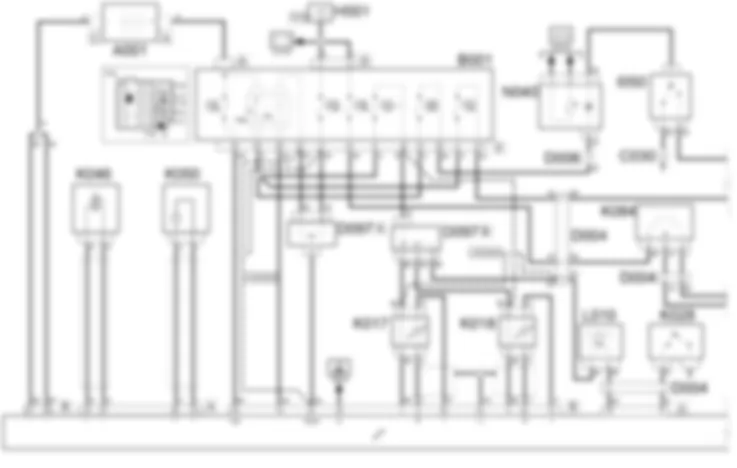

Wiring diagram - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

COMPONENTS - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

| Component code | Description | Reference to the assembly |

| A1 | Battery | |

| B1 | Engine compartment junction unit | |

| C11 | Right front earth | - |

| C30 | Left rear earth | - |

| C60 | Injection control unit earth | - |

| D4 | Front/engine coupling | - |

| D6 | Front/rear coupling | - |

| D97 | Short circuit coupling | - |

| H1 | Ignition switch | |

| K17 | Lambda sensor on catalyzer | |

| K28 | Engine oil pressure sensor | - |

| K28 | Engine oil pressure sensor | |

| K43 | Integrated air temperature sensor | |

| K47 | Timing sensor | |

| K55 | Accelerator pedal potentiometer | |

| K84 | Speedometer sensor | - |

| L10 | Fuel vapour recovery solenoid valve | - |

| L10 | Fuel vapour recovery solenoid valve | |

| M10 | Engine management control unit | |

| N70 | Injector | |

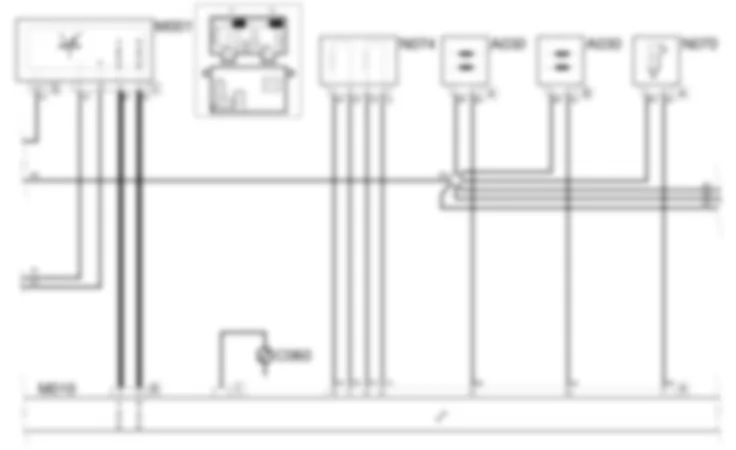

Component location - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

COMPONENTS - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

| Component code | Description | Reference to the assembly |

| A1 | Battery | |

| B1 | Engine compartment junction unit | |

| C11 | Right front earth | - |

| C30 | Left rear earth | - |

| C60 | Injection control unit earth | - |

| D4 | Front/engine coupling | - |

| D6 | Front/rear coupling | - |

| D97 | Short circuit coupling | - |

| H1 | Ignition switch | |

| K17 | Lambda sensor on catalyzer | |

| K28 | Engine oil pressure sensor | - |

| K28 | Engine oil pressure sensor | |

| K43 | Integrated air temperature sensor | |

| K47 | Timing sensor | |

| K55 | Accelerator pedal potentiometer | |

| K84 | Speedometer sensor | - |

| L10 | Fuel vapour recovery solenoid valve | - |

| L10 | Fuel vapour recovery solenoid valve | |

| M10 | Engine management control unit | |

| N70 | Injector | |

Description - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

An electronic control system supervises and governs all engine parameters to optimise performance and fuel consumption by means of a real-time response to different service conditions.The system is managed by a single control unit that controls the twin ignition (static with lost spark) and the injection (phased).Depending on the signals received from numerous sensors, the control unit controls the injectors connected to it managing the following systems:fuel supply;air supply;engine cooling;exhaust with catalytic converter controlled by two lambda sensors;fuel vapour recirculation.

The electronic management system described above ensures that this engine meets the very latest EOBD (European On Board Diagnogis) system emission control and monitoring requirements. This system allows continous diagnosis of emission-related car components and notifies the driver if any of the components should deteriorate by turning on a warning light and showing a message on the instrument panel matrix display.The system is also controlled by dedicated relays in the engine compartment junction unit. Lines supplying the control unit and various system components (sensors and actuators) are protected by dedicated fuses that are also located inside the junction unit.

Operational description - PETROL ENGINES ELECTRONIC MANAGEMENT - Fiat PANDA 1.2 8v

The engine management control unit M010 is connected directly to the battery earth A001 connector G from connector B pin 27, 28.The direct battery power supply is provided at pin 29 connector B, from the line protected by fuse F 18, housed in the engine compartment junction unit B001.The ignition-operated supply is supplied:to the engine management control unit M010, pin 47 connector B:to the coil, incoming, for the relay T09 housed inside the engine compartment junction unit B001;to the speedometer sensor K084, pin 3.

The engine management control unit provides a negative signal, at pin 15 connector B, to the relay T09 coil output.When energized, the relay provides a direct battery power supply:to the Lambda sensors K017 and K018 (at pins 4 respectively);to the fuel vapour recovery solenoid valve L010 (pin 1).to the ignition coils A030, connector A and B (at pins 1 respectively);to the injectors N070, connector A, B, C, D (at pins1 respectively);to the fuel pump motor N040 (pin 4).

With the engine started, the various sensors used in the supply system receive a direct power supply from the engine management control unit, exchanging all information relating to their function with it.From connector A, the control unit M010:at pin 62 receives the signals from the engine coolant temperature sensor K036;at pins 54 and 68 it provides the power supply and reference earth for the built-in air temperature sensor K043;at pins 55 and 75 it receives the absolute air temperature and pressure signals respectively supplied by sensor K043;at pin 26 it controls the fuel vapour recovery solenoid valve L010;at pin 8 it receives the engine oil pressure sensor signal K028;at pins 57, 58, 64, 65 sends the commands to the engine idle actuator N074;at pins 59 and 66 it controls the coils A030;at pins 71, 72, 78, 79 it controls the injectors N070;at pin 76 receives the signal from the throttle position sensor K056;at pins 54, 68 provides the power supply and reference earth for the timing sensor K047;at pins 53 and 67 supplies the engine rpm sensor K046;at pins 56, 70 supplies the detonation sensor K050.

From connector B, the control unit M010:at pins 20, 12 supplies the Lambda sensors K017 and K018 respectively;at pins 8, 24 receives the signals from the Lambda sensors K017and K018 respectively;at pins 1, 2 provides the reference earth for the internal resistances for Lambda sensors K017 and K018;at pin 25 it is connected to the diagnostic socket.

From pins 6, 32, connector B, the engine management control unit M010 is connected to the body computer node M001 via the CAN. The engine management control unit sends/receives the signals supplied by the various sensors used in the system via this line.For more detailsFrom connector C, the engine management control unit M010 is connected to injection control unit earth C060.BATTERY

A001A

A001B

A001C

A001C

A001C

A001D

A001D

A001E

A001F

JUNCTION UNIT

B001A

B001D

B001D

B001D

B001D

B001D

B001D

B001D

RIGHT FRONT EARTH

C011

C011

C011

C011

C011

C011

LEFT REAR EARTH

C030

C030

C030

C030

C030

INJECTION CONTROL UNIT EARTH

C060

C060

C060

FRONT/ENGINE COUPLING

D004

D004

D004

D004

D004

D004

D004

D004

D004

D004

D004

FRONT/REAR COUPLING

D006

D006

D006

D006

SHORT CIRCUITING COUPLING

D097A

D097A

D097A

D097A

D097A

D097B

D097B

D097B

D097B

D097B

D097C

D097C

D097C

D097D

D097E

D097E

D097F

D097G

D097G

D097H

IGNITION SWITCH

H001A

H001A

H001A

H001B

LAMBDA SENSOR ON CATALYZER

K017

K017

ENGINE OIL PRESSURE SENSOR

K028

K028

K028

INTEGRATED AIR TEMPERATURE SENSOR

K043

K043

K043

TIMING SENSOR

K047

K047

K047

ACCELERATOR PEDAL POTENTIOMETER

K055

K055

K055

SPEEDOMETER SENSOR

K084

FUEL VAPOUR RECOVERY SOLENOID VALVE

L010

L010

ENGINE MANAGEMENT ECU

M010A

M010A

M010A

M010B

M010B

M010B

M010B

M010B

M010B

M010B

M010B

M010C

M010C

M010C

INJECTOR

N070A

N070A

N070A

N070B

N070B

N070B

N070C

N070C

N070C

N070D

N070D

N070D