Components - FAP PARTICLE FILTER SYSTEM - Fiat DOBLO 1.3 JTD 16V Fino a 10/2000

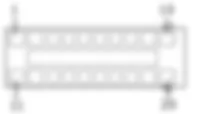

| Component code | Description | Reference to the assembly |

| B001 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| C15 | DASHBOARD EARTH, DRIVER''S SIDE | |

| D004 | FRONT/ENGINE COUPLING | |

| E50 | INSTRUMENT PANEL | |

| H001 | IGNITION SWITCH | |

| K187 | FAP DIFFERENTIAL PRESSURE SENSOR | |

| K190 | DOWNSTREAM PARTICULATE FILTER TEMPERATURE SENSOR (DPF) | |

| M001 | BODY COMPUTER | |

| M010 | ENGINE MANAGEMENT ECU |

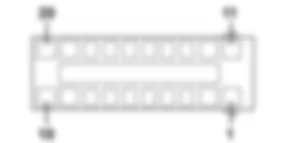

| Component code | Description | Reference to the assembly |

| B001 | JUNCTION UNIT | |

| B2 | JUNCTION UNIT UNDER DASHBOARD | |

| C15 | DASHBOARD EARTH, DRIVER''S SIDE | |

| D004 | FRONT/ENGINE COUPLING | |

| E50 | INSTRUMENT PANEL | |

| H001 | IGNITION SWITCH | |

| K187 | FAP DIFFERENTIAL PRESSURE SENSOR | |

| K190 | DOWNSTREAM PARTICULATE FILTER TEMPERATURE SENSOR (DPF) | |

| M001 | BODY COMPUTER | |

| M010 | ENGINE MANAGEMENT ECU |

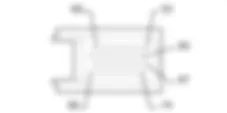

The DPF (Diesel Particulate Filter) is a system designed to keep down the level of particulates in the exhaust systems in diesel engines.The DPF system consists of:- the DPF filter;- sensors and actuators;- specific engine management control unit strategies.Since the filter is an accumulation system, it must be periodically regenerated (cleaned) by burning the particles present in the filter whose quantity is calculated using a control algorithm for the engine management control unit.The engine management control unit uses multiple injections to increase the temperature of the exhaust gases up to around 600°C to burn the particles.The regeneration of the filter takes place by bringing the exhaust gases at the DPF intake to a temperature of >580°C and an O2 content > 5%.The engine management control unit controls the process acting on:- diesel metering (up to 5 injections in the same engine cycle per cylinder);- control of the air (EGR, supercharging pressure).The duration of the regeneration process is variable depending on the type of vehicle and the level of blockage.During this stage the specific calibration of the engine guarantees that there is no discontinuity in the torque supplied in relation to normal operation therefore the customer should not be aware of anything and the regeneration stage should be kept activated in all engine operating conditions.The instrument panel provides the information necessary for the management of the filter regeneration process by means of warning lights and messages.A signal from the particulate trap blocked warning light indicates that the particulate filter must be regenerated and the driving profile does not allow regeneration.If the system cannot carry out the regeneration, the EOBD-engine control system failure warning light is also turned on and a message appears on the display to indicate that the filter cannot be regenerated.For further details,

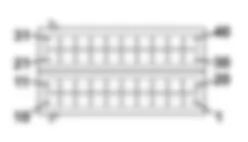

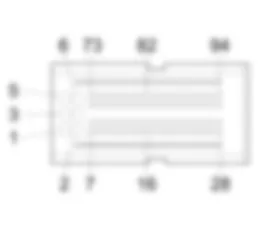

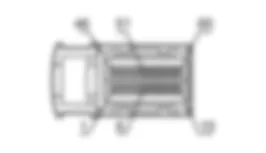

The engine management control unit M10 controls and manages the DPF system with the help of 2 special sensors:- downstream particle filter temperature sensor K190;- DPF differential pressure sensor K187.Sensor K190 receives an earth signal from the engine management control unit M10 - pin 11 of connector A - and sends the temperature signal to pin 91 of connector A of M10.Sensor K187 receives a power supply and an earth signal from the engine management control unit M10 - pin 14 and 33 of connector A - and sends the pressure signal to pin 49 of connector A of M10.The control unit M10 sends, via the B-CAN - pins 58 and 59 of connector A, the signals useful for the display of the warnings lights and messages in the instrument panel E50. This communicates with the system - pins 8 and 9 of connector A - producing the filter regeneration (particulate trap blocked) process management signals or indicating that filter regeneration is not possible (fault in EOBD).

Deutsch

Deutsch English

English English

English Español

Español Français

Français Nederlands

Nederlands Русский

Русский